PS tableware refers to disposable tableware made of polystyrene (PS) as the main raw material, which is widely used in fast food, take-out, banquets, airline catering and other fields. Polystyrene is a non-toxic, odorless, lightweight thermoplastic with good formability and processability. It has been used in food contact fields for decades.

Heat resistance of polystyrene

The softening point of PS is usually around 90℃, and the glass transition temperature is about 100℃. In conventional injection molding grades, the heat resistance limit is generally set to 80℃. Under non-pressurized conditions, PS tableware can be in short-term contact with hot food or hot drinks within 80℃ without structural deformation or release of harmful substances. Experimental data show that high-quality PS tableware is soaked in 70℃ hot water for 30 minutes without obvious deformation and no precipitate on the surface, which meets food contact safety standards.

Analysis of cold resistance of polystyrene

PS material maintains high dimensional stability under low temperature conditions, and its minimum operating temperature can reach -20℃. In applications such as cold chain transportation, ice cream packaging, and cold meal delivery, PS tableware can withstand temperatures below freezing without cracking. Especially in the distribution of quick-frozen foods and cold drinks, PS tableware exhibits good resistance to cold cracking. Conventional tests show that the PS spoon is taken out for use after being refrigerated at -18℃ for 24 hours, and there is no significant decrease in strength and it is not easy to break.

|

|

The value of PS tableware's cold and hot tolerance for practical applications

Strong compatibility with hot food: In daily applications, the temperature of foods such as hot soup, rice, and hot dishes generally does not exceed 70℃, and PS tableware can fully meet such needs. It is particularly suitable for high-turnover scenarios such as fast food chains, boxed lunch delivery, and event catering.

Excellent cold chain adaptability: In categories such as cold drinks, jellies, ice cream, and small-package quick-frozen foods, PS tableware does not shrink or crack, and is one of the preferred materials in the field of low-temperature foods.

Strong stability: During the alternating process of hot and cold, the deformation rate of PS tableware is much lower than that of other low-cost plastics. Even in scenarios where hot and cold are switched quickly (such as from refrigeration to heating), the structural integrity is still good, which improves the user experience.

Safety standard guarantee: high-quality PS tableware can pass food contact test standards such as FDA, EU 10/2011, GB 4806.7, etc. Its cold and heat tolerance is not only reflected in the physical dimension, but also in the chemical safety, avoiding the release of risk substances such as bisphenol A and phthalate when in contact with high temperature.

Advantages of PS tableware over other materials

Thermal stability better than PLA materials: PLA (polylactic acid) degradable materials have a heat deformation temperature lower than 60°C and are easily softened in hot soup and other scenes. The upper limit of PS heat resistance is significantly higher than PLA, and it is suitable for a wider range of food types.

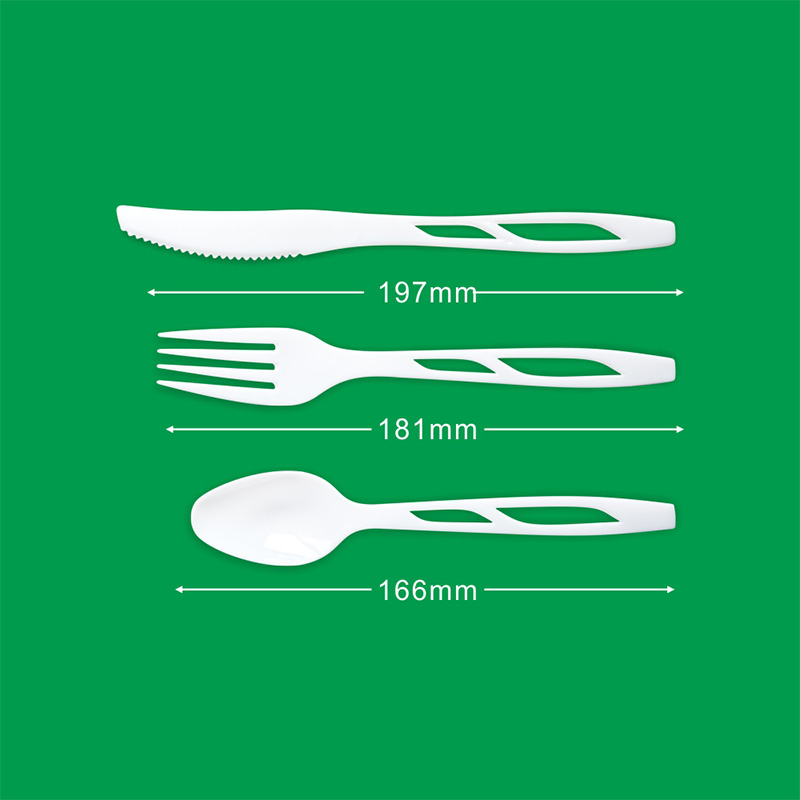

Rigidity experience better than PP materials: Although polypropylene (PP) materials have slightly higher heat resistance (up to 100°C), PS tableware is better in feel, strength and molding accuracy, especially in knife, fork and spoon products that require a stiff structure, PS has obvious advantages.

More textured appearance: PS has high gloss and transparency, and can produce disposable tableware with a glass-like effect, improving the overall visual and brand grade.

English

English 中文简体

中文简体