Changya New Material Technology Co., Ltd. was founded in 2013, and the group is headquartered in Ningbo, China. It is a limited liability company integrating R&D, production and sales. As China Disposable PLA Straws Manufacturers and Printed PLA Straws Suppliers, the company mainly produces paper PLA & Plastic disposable tableware, such as straw, cutlery, microwaveable box, hinged box, cup, carry out bag, plate, dinning kit, etc.

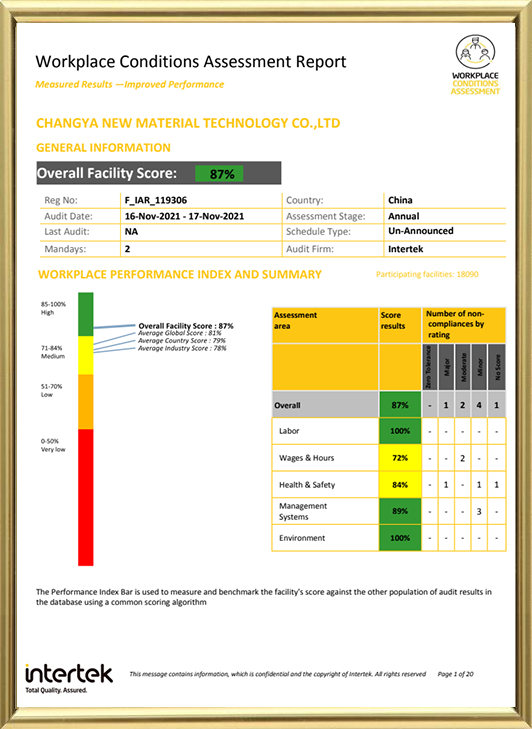

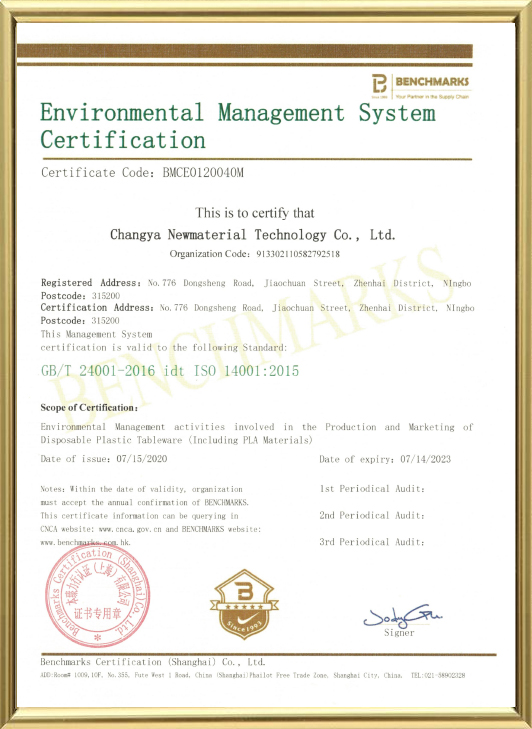

Changya New Material Technology Co., Ltd. has developed rapidly since its establishment, with a growth rate of over 30% each year, and has now become an enterprise in the field of high-quality disposable food and kitchen supplies in China. Changya products are mainly sold in the international market, and more than 90% of the products are exported to many regions such as Europe, the United States, and Australia. Changya adopts strict quality control standards for its products and has won a variety of international certifications, including BRC, GMP NSF, ISO 22000, and GMP, and it has passed LFGB, FDA, and other food safety tests. At the same time, it is a member of the international human rights organizations BSCI and Sedex. It has wide recognition and a good reputation in the international market.

The Rise of Disposable Wooden Cutlery in a Plastic-Free Era In the context of t...

View MoreThe Rise of Disposable Wooden Cutlery in a Plastic-Free Era Over the past decade...

View MoreIdentifying Microwaveable Disposable Containers When selecting disposable tablew...

View MoreMaterial Determines Safety: Which Disposable Cups are Microwaveable? When choosi...

View MoreSuperior Thermal Performance and Microwave Safe Characteristics The most promine...

View MoreMaterial Properties and Chemical Stability Polypropylene (PP) is a semi-crystall...

View MoreIn recent years, the global concern over plastic pollution has reached critical levels, with single-use plastic items, such as straws, becoming one of the most commonly found pollutants in oceans, rivers, and beaches. In response, various alternatives have been introduced to reduce the environmental impact of plastic waste, with disposable PLA straws emerging as a prominent eco-friendly option.

PLA straws are often marketed as a sustainable replacement for traditional plastic straws, which are made from petroleum-based plastics like polyethylene or polypropylene. While disposable PLA straws offer a promising alternative to conventional plastics, their environmental impact is not entirely without complexity. To truly understand the benefits of PLA straws, we need to explore their composition, how they are made, and the conditions under which they can be properly disposed of.

This guide will cover the following key points:

The thesis of this article is clear: Disposable PLA straws offer a more sustainable option compared to plastic, but understanding their properties and proper disposal methods is crucial in ensuring they have a minimal environmental footprint.

Polylactic Acid (PLA) is a biodegradable plastic made from renewable plant-based materials like corn starch, sugarcane, or tapioca roots. Unlike conventional plastics that rely on fossil fuels, PLA straws are derived from agricultural resources, making them a more eco-friendly alternative. PLA is often referred to as a bioplastic because it is biodegradable and compostable under specific conditions.

1. Fermentation of Plant Sugars: PLA is produced by fermenting plant-based sugars, typically extracted from corn or sugarcane. These sugars are converted into lactic acid through a fermentation process, where bacteria break down the sugars into lactic acid.

2. Polymerization: The lactic acid is then chemically polymerized to form polylactic acid, which can be molded into various shapes, including straws, cups, and other single-use products.

3. Molding into Products: Once the PLA polymer is created, it is processed into products such as disposable straws through injection molding or extrusion.

Traditional plastic straws are made from petroleum-based products, which contribute to fossil fuel consumption and the depletion of natural resources. PLA, on the other hand, is made from renewable plant resources, offering a significant reduction in reliance on non-renewable energy sources.

The production of PLA straws generally results in a lower carbon footprint compared to conventional plastic. The carbon emissions associated with producing PLA are significantly lower because it uses agricultural resources, which absorb carbon dioxide during their growth, helping to offset some of the emissions produced during manufacturing.

One of the biggest benefits of PLA straws is their ability to break down over time in industrial composting systems. Unlike plastic straws that can remain in landfills or oceans for hundreds of years, PLA straws degrade into natural elements (primarily carbon dioxide and water) in the right composting conditions. This significantly reduces the risk of environmental pollution.

PLA is made from food-safe materials and is non-toxic, making it a safer choice for single-use items in food and beverage industries. Unlike some traditional plastics, which can contain harmful chemicals like BPA, PLA does not leach dangerous substances when in contact with food or beverages.

While PLA is biodegradable, it requires specific conditions to break down. In home compost bins or natural environments, PLA straws may not degrade quickly, if at all. This is because PLA needs a high-temperature, high-humidity environment, typically found in industrial composting facilities, to decompose properly. Without access to such facilities, PLA may end up in landfills, where it could take years to break down.

Another problem with PLA straws is the potential for contamination of plastic recycling streams. If PLA straws are mistakenly mixed with conventional plastics during recycling, they can cause significant problems. PLA cannot be recycled in the same way as traditional plastics, so it's crucial to keep them separate from plastic waste to avoid cross-contamination.

Many regions do not have the necessary industrial composting facilities to process PLA materials. Without widespread access to these systems, the benefits of PLA straws in terms of reducing plastic pollution can be diminished. This creates a significant challenge for cities, towns, and regions that lack the infrastructure to handle PLA waste properly.

While PLA is derived from renewable resources, its production process still has some environmental drawbacks. For example:

When evaluating disposable PLA straws, it's important to compare them with other commonly used alternatives to plastic straws. The aim is to assess the environmental impact, usability, cost, and sustainability of PLA straws in comparison to other eco-friendly options like paper straws, stainless steel straws, and reusable silicone or bamboo straws. Each alternative has its advantages and limitations depending on the specific context in which it's used.

Paper straws have emerged as one of the most common alternatives to plastic straws. They are often used in cafes, restaurants, and at events as part of the movement toward more sustainable options. Let’s compare PLA straws and paper straws in terms of environmental performance, durability, and practicality.

| Aspect | PLA Straws | Paper Straws |

|---|---|---|

| Material | Bioplastic made from renewable plant sources (corn, sugarcane) | Made from paper, typically sourced from trees |

| Production Impact | Requires energy for fermentation and polymerization, uses agricultural land | Requires trees and significant water; also involves energy for manufacturing |

| Biodegradability | Biodegradable under industrial composting (3-6 months) | Biodegradable in most environments (composts within weeks) |

| Disposal | Needs industrial composting or specialized recycling | Can be composted in industrial facilities or landfills |

| Durability | More durable than paper; can handle liquids for longer periods without breaking down | Weakens quickly in liquids, typically becomes soggy and soft |

| Environmental Concerns | Needs proper composting infrastructure; improper disposal can result in slow degradation | Paper production can contribute to deforestation if not sourced sustainably; still generates waste in landfills |

| Cost | Typically more expensive than paper straws | Generally cheaper than PLA straws, but can vary depending on quality |

| Availability | More limited availability compared to paper straws, especially in regions without composting facilities | Widely available in various regions, commonly used in many businesses and events |

Reusable straws are gaining popularity due to their long-term sustainability, as they can be used hundreds or thousands of times. These include options like stainless steel, bamboo, and silicone. Here’s a breakdown of how PLA straws compare to these reusable alternatives:

| Aspect | PLA Straws | Reusable Straws (Stainless Steel, Bamboo, Silicone) |

|---|---|---|

| Material | Bioplastic made from renewable plant sources (corn, sugarcane) | Stainless steel, bamboo, silicone (all non-disposable) |

| Production Impact | Requires energy for fermentation and polymerization, uses agricultural land | Stainless steel requires energy-intensive metal production; bamboo and silicone are more sustainable, but bamboo still requires land use |

| Durability | Designed for single-use; more durable than paper, but still disposable | Reusable for hundreds to thousands of uses; very durable |

| Biodegradability | Biodegradable under industrial composting | Not biodegradable, but highly durable and long-lasting |

| Disposal | Needs industrial composting or recycling (if available) | Can be reused indefinitely; no need for disposal |

| Environmental Concerns | Requires proper composting infrastructure; improper disposal can lead to waste | Reusable options have little environmental impact after production, but disposal of damaged items (e.g., broken bamboo) can contribute to waste |

| Cost | Typically more expensive than paper or plastic straws | High initial cost, but can be cost-effective in the long run due to reusability |

| Availability | Available in most eco-friendly stores and online, but less common than paper straws | Available in various materials; widely available but can vary in price depending on the material |

Apart from PLA, other bioplastics such as PHA (Polyhydroxyalkanoates) and CPLA (Crystallized PLA) are being developed as alternatives to traditional plastics. Here’s how PLA straws compare to other bioplastic straws:

| Aspect | PLA Straws | PHA Straws | CPLA Straws |

|---|---|---|---|

| Material | Polylactic Acid (made from plant sugars) | Polyhydroxyalkanoates (produced by bacteria) | Crystallized PLA (modified PLA with higher melting point) |

| Production Impact | Requires agricultural land (corn, sugarcane) | Produced by bacteria from organic waste or sugars; uses less agricultural land | Similar to PLA, but with slightly higher energy and material costs |

| Biodegradability | Biodegradable in industrial composting (3-6 months) | Fully biodegradable in natural environments (soil, marine) | Biodegradable, but may require industrial composting |

| Disposal | Needs industrial composting or specialized recycling | Can degrade in both industrial composting and natural environments | Requires industrial composting for optimal degradation |

| Environmental Concerns | Requires land and water for crops, potentially pesticide use | Less land and water use; biodegradable in natural environments | Similar to PLA but with slightly higher environmental cost |

| Cost | Relatively affordable, but still more expensive than paper | More expensive due to complex production processes | Similar to PLA but slightly higher cost |

| Availability | Widely available in eco-friendly markets | Limited availability compared to PLA | Increasingly available as a more durable alternative |

Proper disposal is a critical factor in ensuring that disposable PLA straws truly live up to their environmental benefits. As biodegradable and compostable products, PLA straws can be an excellent alternative to plastic, but only if they are disposed of in the correct manner. Improper disposal—such as sending them to landfills or mixing them with conventional plastics in recycling bins—can hinder their ability to break down and result in missed opportunities for sustainability.

PLA straws are made from renewable plant-based materials (such as corn or sugarcane), which are biodegradable under the right conditions. However, they require industrial composting to break down effectively, which is very different from traditional home composting or landfill conditions. In industrial composting facilities, the combination of high temperatures, humidity, and microbial activity speeds up the breakdown of PLA straws, allowing them to degrade within 3 to 6 months.

In contrast, home composting or landfill disposal is not sufficient for PLA, as the conditions are not ideal for biodegradation. In landfills, PLA can take years to break down and may even release harmful greenhouse gases like methane as it decomposes anaerobically.

| Disposal Method | PLA Straw Breakdown | Benefits | Challenges |

|---|---|---|---|

| Industrial Composting | Breaks down fully in 3 to 6 months under optimal conditions | Quick decomposition due to high temperature and humidity | Requires access to industrial composting facilities |

| Home Composting | Very slow or incomplete breakdown (may take years) | Low-cost, convenient if composting is available at home | Does not provide the necessary temperature for effective breakdown |

| Landfill Disposal | Decomposes slowly, potentially emitting methane | Easy disposal option, but not ideal for sustainability | Creates environmental harm due to slow breakdown and methane emission |

| Recycling (with bioplastics) | Incompatible with traditional plastic recycling systems | Allows bioplastics to be recycled or repurposed (if available) | Not widely available for PLA, contamination risk in recycling systems |

For consumers and businesses who want to ensure their PLA straws are disposed of properly, finding local composting facilities is essential. Many cities and communities are adopting waste diversion programs, where residents can send biodegradable products (including PLA) to composting facilities. However, finding these locations or services can be difficult without the right guidance.

| Option | Description | Pros | Cons |

|---|---|---|---|

| Municipal Composting Programs | Local government-run composting programs that accept PLA | Convenient for residents, often part of curbside services | Not all areas accept PLA products; varies by region |

| Private/Industrial Facilities | Specialized facilities for large-scale composting of PLA | Can handle large volumes, ideal for businesses | Not always available to consumers, limited in some areas |

| Community Composting Programs | Local community-run composting initiatives | More personalized, often smaller scale | Limited locations, may not accept large quantities of PLA |

If there are no industrial composting facilities in your area, PLA straws may still have some options, but it’s important to focus on reducing environmental harm through thoughtful alternatives:

| Alternative Option | Description | Pros | Cons |

|---|---|---|---|

| Reduce Use of PLA Straws | Minimize single-use straw consumption | No waste created if straws are not used | May not be feasible in all situations (e.g., restaurants) |

| Switch to Other Biodegradable Products | Use paper straws or other biodegradable options | Easier to compost or dispose of in the environment | Paper straws can become soggy and aren’t as durable |

| Proper Landfill Disposal | If composting isn’t possible, send PLA to the landfill | Ensures that PLA does not contaminate recycling streams | PLA can still release methane and break down slowly in landfills |

One way to improve the proper disposal of PLA straws is through clear labeling on products. Manufacturers and retailers should use labels to guide consumers about the correct disposal method for PLA products. Labels might indicate:

These labels can help improve the likelihood that PLA products are disposed of correctly, maximizing their environmental benefits.

Finally, consumer education is critical to ensuring the successful disposal of PLA straws. Governments, businesses, and environmental organizations must collaborate to create awareness about the importance of proper disposal and composting.

As environmental concerns continue to grow, the future of disposable PLA straws and other sustainable alternatives is a critical topic. This section will explore the potential for PLA straws to contribute to a more sustainable future, the challenges that need to be addressed, and the innovations that are shaping the future of eco-friendly disposables.

The production of PLA straws has evolved significantly over the past decade. New technologies and processes are continuously being developed to improve the sustainability of PLA, reduce its environmental impact, and expand its applications. Here are some innovations and trends in PLA and bioplastic production:

| Innovation | Description | Potential Benefits |

|---|---|---|

| Improved Production Efficiency | Optimization of fermentation processes to reduce energy and resource usage | Lower environmental impact, cost reduction |

| Sustainable Feedstocks | Use of agricultural waste, algae, or food waste for PLA production | Reduced land, water, and chemical usage |

| Hybrid Bioplastics | PLA blends with other biodegradable polymers or fibers | Enhanced strength, improved durability, faster biodegradation |

| Nano-materials in PLA | Incorporation of nano-materials to improve PLA performance | Stronger materials with improved biodegradability |

Governments around the world are introducing policies and legislation aimed at reducing single-use plastics and encouraging the use of sustainable alternatives. PLA straws may play a key role in these initiatives, but their success depends on how legislation addresses issues like composting infrastructure, bioplastic standards, and consumer education. Key aspects include:

| Policy or Legislation | Description | Impact on PLA Straws |

|---|---|---|

| Ban on Single-Use Plastics | Legislation restricting or banning plastic straws | PLA straws could become more popular as an alternative |

| Industrial Composting Standards | Regulations to ensure PLA is properly composted | Increased need for industrial composting infrastructure |

| Extended Producer Responsibility (EPR) | Manufacturers must take responsibility for product lifecycle | Manufacturers of PLA straws must ensure proper disposal options |

| Public Education and Awareness | Government campaigns on proper disposal and sustainability | Encourages consumers to dispose of PLA properly, increasing effectiveness |

While PLA straws offer a promising sustainable alternative to plastic, there are still challenges that need to be overcome in order to make them a mainstream solution. Here are some of the key challenges for the future of disposable PLA straws:

>

| Challenge | Description | Impact on PLA Straws |

|---|---|---|

| Lack of Composting Infrastructure | Limited availability of industrial composting facilities | PLA may not be composted properly, ending up in landfills |

| Public Confusion | Consumers are unsure of how to dispose of PLA | Incorrect disposal could negate the benefits of PLA straws |

| Cost and Availability | PLA straws are more expensive than plastic straws | High cost may limit adoption, especially for small businesses |

| Performance in Hot Beverages | PLA straws can deform in hot beverages due to low melting point | Limits use for hot drink applications |

| Recycling Issues | PLA is incompatible with most plastic recycling streams | Risk of contamination in recycling systems |

Here are some of the most frequently asked questions (FAQs) about disposable PLA straws. This section addresses common concerns and provides clear answers to help you better understand their environmental benefits, usage, and disposal methods.

PLA straws are made from polylactic acid (PLA), which is derived from plant-based materials such as corn, sugarcane, or cassava. PLA is a type of bioplastic that offers a sustainable alternative to traditional petroleum-based plastics.

Yes, PLA straws are biodegradable, but they require specific conditions to break down effectively. They biodegrade in industrial composting facilities where conditions like high temperature, humidity, and the presence of microorganisms accelerate the process.

| Condition | PLA Straws | Paper Straws |

|---|---|---|

| Home Composting | Not effective, needs industrial composting | Can compost in home composting, depending on conditions |

| Industrial Composting | Effective breakdown in 3-6 months | Effective breakdown in 3-6 months |

| Landfill | Decomposes slowly, may release methane | Decomposes slowly, can take up to a year |

The decomposition time of PLA straws varies based on where they are disposed of:

| Disposal Method | Decomposition Time | Comments |

|---|---|---|

| Industrial Composting | 3 to 6 months | Requires high temperature and humidity |

| Home Composting | 1-2 years, or may not decompose at all | Requires ideal conditions for biodegradation |

| Landfill | Several years or longer | Methane emissions may occur, slow breakdown |

No, PLA straws cannot be recycled with conventional plastic recycling programs. PLA is a type of bioplastic, and it can contaminate traditional plastic recycling streams if mixed in. This is because PLA requires specific processing conditions different from those used for traditional plastics like PET and PVC.

| Recycling | PLA Straws | Plastic Straws |

|---|---|---|

| Standard Plastic Recycling | Not recyclable in typical recycling streams | Can be recycled in some places, often turns into downcycled products |

| Bioplastic Recycling | Requires specialized facilities for bioplastics | Not applicable |

Yes, PLA straws are generally food-safe and non-toxic. PLA is made from natural plant-based materials and does not contain harmful chemicals found in traditional plastics like BPA (bisphenol A). As such, they are safe for use in beverages, including hot and cold drinks, within the temperature limits of PLA.

No, PLA straws are not ideal for hot drinks. PLA has a low melting point (around 60°C or 140°F), meaning it can soften or melt when exposed to temperatures above this threshold. For hot beverages like coffee, tea, or hot chocolate, metal or silicone straws would be a better alternative.

| Type of Straw | Best Use | Hot Drink Suitability |

|---|---|---|

| PLA Straws | Best for cold drinks | Not recommended for hot drinks |

| Paper Straws | Best for cold drinks, but can be used for short periods in hot drinks | Not recommended for hot drinks |

| Metal Straws | Ideal for all drinks | Can handle hot beverages |

| Silicone Straws | Ideal for all drinks, especially hot drinks | Ideal for hot drinks |

Proper disposal of PLA straws is essential for ensuring their environmental benefits. PLA straws should not be thrown into the regular trash or recycling bins. Here’s what you should do:

Yes, PLA straws are a more sustainable option than traditional plastic straws. They offer the following advantages over conventional plastic straws:

However, for the best environmental outcome, PLA straws must be disposed of properly through industrial composting.

| Feature | PLA Straws | Plastic Straws |

|---|---|---|

| Material | Derived from plant-based sources | Made from petroleum-based plastics |

| Biodegradability | Biodegradable in industrial composting | Non-biodegradable |

| Environmental Impact | Lower impact compared to plastic | High environmental impact due to non-decomposition |

| Toxicity | Non-toxic | May contain harmful chemicals (e.g., BPA) |

Yes, PLA straws tend to be more expensive than traditional plastic straws. This is primarily due to the higher cost of producing bioplastics, the use of renewable resources, and the need for industrial composting infrastructure. However, as demand for eco-friendly products grows, the cost gap between PLA and plastic straws is expected to narrow.

| Straw Type | Cost per Straw | Explanation |

|---|---|---|

| PLA Straws | Higher than plastic straws | Production costs and bioplastic material |

| Plastic Straws | Lower | Made from petroleum-based plastic |